Front End Repair and Suspension Services

Foreign | Domestic | Electric | Hybrid

Boca Raton

(561) 672-1281

Royal Palm Beach

(561) 753-6122

Wellington

(561) 753-6101

- We Repair All Makes & Models

We have the best warranties in the business. Period.

- Same-Day Appointments & Repair Services

Free Vehicle Pickup & Drop-Off

- ASE-Certified Master Mechanics

Front End Repair and Suspension Services

![]()

We Repair All Makes & Models

100% Parts And Labor Warranty

- Same Day Appointments & Repair Services

Free Vehicle Pick-Up & Drop-Off

ASE Certified Mechanics

Boca Raton

(561) 672-1281

Royal Palm Beach

(561) 753-6122

Wellington

(561) 753-6101

Bill Tyson’s Auto Repair will service and repair all of your vehicle’s suspension components and operational systems to ensure impeccable ride quality. Any loss of the suspension’s operation could be dangerous, causing extensive damage to your vehicle and potentially fatal to you, your passengers, or others.

Our ASE-certified technicians in our suspension shops in Palm Beach County, FL are trained to inspect and service today’s complex suspensions as well as vintage, classic car, and simple suspension systems.

Some of the Components We Service and Repair

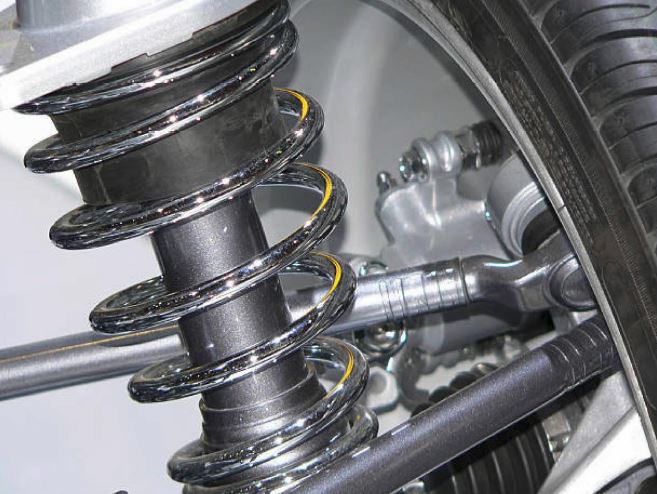

- Shock absorbers and struts

- Steering systems

- Springs

- Wheels and tires

- Linkages

- Electric power steering

- Bushings, bearings, and joints

- Hydraulic power steering

- Vehicle Suspension Alignment

Vehicles We Specialize in for Front End and Alignment Service and Repair

Mercedes | BMW | Land Rover | Range Rover | Jaguar | Audi | GM | Chevrolet | Chevy | Buick | Pontiac | Dodge | Chrysler | Tesla | Volt | Toyota | Honda | Nissan

Frequently Asked Questions

Ball Joints

Many parts in your vehicle are important for safe driving, and a ball joint is one of them. A ball joint is a part of the front suspension that connects the control arm to the steering knuckle that holds the front wheel. The connection flexes, allowing the front wheel to steer and move up and down. Modern cars have at least two ball joints in the front end; many trucks have four. Ball joints are built into the control arm and may be replaced as one unit.

A ball joint consists of a housing (socket) and a stud with a ball; it serves as a flexible joint. In some trucks and older vehicles, ball joints have grease fittings and need to be greased periodically. Most modern cars have non-serviceable ball joints that are factory-greased and sealed with a dust boot. That’s why it is important to call our suspension shops in Palm Beach County, FL so we can handle these issues for you.

Ball joints need to be inspected periodically and replaced if loose or worn. Some may last over 160,000 miles, but bad roads, speed bumps, and winter road salts can prematurely cause ball joint failure. A badly worn ball joint can even separate, causing a vehicle to lose steering control and creating a very dangerous situation. You may have seen an older car with one of the front wheels collapsed under the vehicle, indicating that it was most likely caused by ball joint failure.

A “visual inspection” cannot properly inspect ball joints. To check a ball joint, the front wheel has to be lifted off the ground on a hoist. In some trucks, checking the ball joints is not a simple task: load-carrying ball joints, for example, must be unloaded for proper inspection. We have specific instructions from various vehicle manufacturers on how to inspect ball joints and when a ball joint is determined to be bad.

A ball joint should be replaced if it is loose, has excessive play, or if the dust boot is broken or torn. A damaged dust boot allows the grease to escape, allowing water and dirt to get to the ball joint. In either case, a ball joint won’t last long. In some vehicles, grease fittings serve as ball joint wear indicators. Having a bad ball joint is considered unsafe.

It’s a good idea to replace a ball joint if it shows early signs of wear, if it looks dry (lacks grease), or if it shows excessive rust damage. A major cause of ball joint failures is corrosion damage. A creaking or squeaking noise when driving slowly over large bumps or when turning the steering wheel may be a ball joint that lacks grease. Several steering and suspension components can produce a creaking noise; all must be diagnosed properly, which can be handled expertly by our suspension shops in Palm Beach County, FL.

A knocking or creaking noise coming from the front end when going over bumps is a sign of a bad ball joint. Loose steering and front end excessive play, especially while going over bumps. Importantly, some vehicles will not produce any noticeable symptoms, even if they’re bad, making it imperative to have the vehicle inspected regularly. If your car needs new ball joints and is out of warranty, check with a local dealer and research whether your car manufacturer issued recalls and service campaign bulletins related to ball joints or other vehicle safety issues.

Use good-quality parts if you have to replace ball joints; it’s an investment in safety for you and your passengers. Avoid using cheap aftermarket ball joints that are known to have failed within a year or two.

Often, when one ball joint is bad, the other could be worn out, too, but it’s not necessary. In some pickup trucks with double-arm front suspension, the upper and lower ball joints on one side are often replaced at the same time if the labor overlaps.

In some vehicles, ball joints are riveted or threaded into the control arm. This type is a bit more difficult to replace, and the repair will cost more.

In many vehicles, ball joints are press-fitted into the control arms or steering knuckles (spindles). This type of ball joint must be pressed out using special tools, which takes more time and costs. Rarely can a new ball joint be pressed back in safely, so it’s highly advised to visit Bill Tyson suspension shops in Palm Beach County, FL, to get these items replaced together alongside the steering knuckle or the control arm.

In some vehicles, wheel alignment must be performed after ball joint replacement, another task that our suspension shops can take care of.

Alignments

The process of checking and adjusting the angles of the wheels relative to each other and to the car body or frame is a wheel alignment. The vehicle is placed on an alignment rack to perform the wheel alignment. Special sensors are then mounted to each of the four wheels or only two wheels for front or rear alignments (4-wheel alignment is the best option). A computer is used to then measure the actual angles of the wheel sensors (called toe, camber, caster, etc.) Our technician compares the angles to the specific alignment specs for the vehicle and then corrects the wheel angles accordingly. Before the wheel alignment, our technician will test drive the vehicle, adjust the tire pressure, as well as check the ride height and basic suspension and steering components (e.g. ball joint, tie rod, strut).

If any of the steering or suspension components are bad, they should be replaced before the wheel alignment. After the alignment, you can print out a chart showing the wheel angles before and after the alignment.

Over time, the wheel angles change, and because of this, a wheel alignment is required, which our suspension shops in Palm Beach County, FL can repair. Angles change because of the deformation and wear of various rubber bushings in the vehicle suspension, including sagging springs. After hitting large potholes, curbs, speed bumps, or an accident, the wheel alignment needs to be checked. Replacements of major suspension or steering components require a wheel alignment well. Similarly, it should be done when lowering or raising the suspension heights.

Symptoms of improper wheel alignment:

- When driving straight, the steering wheel is off-center

- When driving on a straight and level road, the vehicle pulls to one side

- The vehicle feels unstable, wanders from side to side, doesn’t hold the road well

- Tires screech when turning

- Uneven tire wear

We recommend doing the wheel alignment every two to three years or if there are signs that the alignment is off. A wheel alignment is recommended when new tires are installed. If your car has wider tires or is a sports car, alignments should be done more often. Re-checking the wheel alignment after a year or two of driving usually shows that it will be slightly out of alignment. After hitting a large bump, the alignment will most likely be off, but if your vehicle holds the road well and the tires are wearing evenly, doing the wheel alignment every year is not necessary. Car maker’s vehicle maintenance schedules typically don’t include the wheel alignment timetables, but it’s advised to check if a tire is worn unevenly.

Your vehicle’s suspension and steering components will last longer, handle better and your tires will get better mileage. If you have a sporty car or wide tires, after the wheel alignment, you’ll notice that the car holds the road better and feels more stable. That’s why it’s important to visit our suspension shops in Palm Beach County, FL, so your car continues to drive like a dream.

Shocks & Struts

It’s usually recommended to replace them in pairs, both front struts or both rear shocks because a new shock absorber will absorb road bumps better than the old one, but it’s not required. If you replace only one shock absorber, it may create an “unevenness” from side to side when driving over bumps. However, if your car is a newer model replacing only one strut or shock absorber may be enough since the opposite side is most likely still good.

It is only necessary if they are all bad. If your truck or SUV has four old shock absorbers and you want your vehicle to have a bit smoother ride, why not replace them all at the same time since they are not very expensive to replace?

Not typically, but in some vehicles, sway bar links are connected to the struts, and a sway bar link must be removed to replace the strut. The nut that holds the sway bar link sometimes seizes up, making it almost impossible to remove without damaging the link. In these rare cases, replacing the sway bar link will be required, and fortunately, they’re not very expensive. Replacing struts involves removing coil springs that are under high tension and is very dangerous to be done at home as a DIY project. It’s best to trust this job to Bill Tyson Auto Repair suspension shops in Palm Beach County, FL, because we have special spring compressor tools that can safely assemble or disassemble a loaded strut. Replacing shock absorbers is less expensive and in most vehicles, a wheel alignment is not necessary when the shock absorber is replaced. At Bill Tyson Auto Repair, we can use original manufacturer parts or save you money with deep discounts using top-quality aftermarket parts. Either way, they’re backed with the best warranties in the business.

Tie Rod Ends

A tie rod is a vital part of the steering system. Large SUVs, pickup trucks, and some older cars have a steering system that uses a recirculating ball mechanism. Many modern cars are equipped with rack-and-pinion steering. In both systems, tie rods have the same operational function: they connect the steering rack or linkage to the steering knuckles. A tie rod works in the rack and pinion steering system and is attached to the vehicle body, frame, or subframe. Steering knuckles function to hold the front wheels in position. When you turn the steering wheel, the steering rack moves and the tie rods turn the steering knuckles in the turning direction.

The two components that make up a tie rod are the inner and outer tie rod ends. Both tie rod ends have ball joints. The inner tie rod end is greased and protected by the steering rack boot. The outer tie rod end is too filled with grease, but it’s protected by a small boot made of rubber or plastic. A common problem with the tie rod ends is that they wear out and get loose. The keen eyes at Bill Tyson’s Auto Repair suspension shops in Palm Beach County, FL would be able to point this out for you. This typically happens when a rubber boot breaks or cracks and dirt or moisture penetrates the inside of the tie rod end, causing wear or corrosion. The outer tie rod ends typically fail more often. With heavier cars and SUVs, greater loads, tie rod problems are more common. A major safety concern is loose tie rod separation causing the vehicle to lose steering control. Disabled vehicles seen with the front wheels pointing in different directions could be caused by tie rod ends having separated.

Indication of a loose tie rod end includes a clunking, rattling, or knocking noise in the front end and looseness felt in the steering. Unfortunately, a loose tie rod end may not produce any symptoms, and it is important to have your mechanic annually check the steering system, brakes, suspension, and other components. The only way to properly inspect tie rods and other steering and suspension components is by having the vehicle raised on a lift.

Yes, looseness in the steering is caused by excessively worn tie rod ends. Shaking in the front end may come and go at certain speeds. This problem is especially common with a recirculating ball steering system used in older SUVs and pickup trucks. A weak steering damper makes the problem worse.

Yes, steering angles are controlled by the tie rods. To adjust steering angles, the thread or clamp connecting the inner and outer tie rods is used. After any of the tie rod ends are replaced, the vehicle will need a wheel alignment to bring the steering and suspension angles back to within specifications. Wheel alignments are an additional cost at our suspension shops in Palm Beach County, FL.

If a tie rod is in good shape, there’s no need to replace it. Often, tie rods on both sides wear out at the same rate, and if one tie rod end is bad and the other is starting to go, it’s best to replace both. Doing both at the same time only requires one wheel alignment. A damaged protective boot is another good reason to replace a working tie rod end. With a damaged boot, the tie rod won’t last long.

If the tie rod end is good, there’s no need to replace it.

Some tie rod ends have grease fittings and must be greased periodically. With many modern cars, tie rod ends are filled with grease and sealed at the factory and don’t need any maintenance. See your owner’s manual or ask your mechanic to check if tie rods have grease fittings or not, during a regular service.

If any of the steering or suspension components are bad, they should be replaced before the wheel alignment. After the alignment, you can print out a chart showing the wheel angles before and after the alignment.

Wheel Balancing

Your wheels are the connection between your vehicle’s chassis and the road surface. When your wheels are out of balance, your connection to the road surface is compromised. Driving with out-of-balance wheels in various road conditions can compound the effects that bumps, road irregularities, and other hazards already are causing to your vehicle’s suspension. Our suspension shops in Palm Beach County, FL put your safety first by making sure your wheels are balanced. A well-balanced set of wheels will minimize any additional wear and tear that normal road usage causes.

Whenever you are getting new tires, it’s a normal service to have the wheels balanced at that time. Some other possible reasons you may need to get them balanced are:

- Vibration in the steering wheel, the floorboard, or your seat

- During the recommended tire rotation service

- Every two years with normal driving or yearly with rough road driving

- After getting a flat or tire repair

- Uneven tire wear

- Tire rim balancing weight falls off

Both are a regular part of vehicle suspension maintenance, but wheel balancing isn’t the same as getting a wheel alignment. A wheel alignment corrects the angles of the tires so they travel in the same direction and make contact with the road properly. Alignment reduces uneven tire wear and extends the life of your tires. Having a wheel balanced fixes any balancing irregularities that the tire on the rim may have when spinning at high speeds. Weights are added to the rims to counteract any imbalances.